Gas Scrubbing

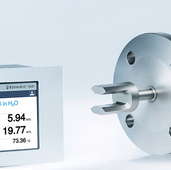

Ultrasonic technology allows continuous and precise adjustment of the alkali supply or excess alkali by measuring the concentration of the washing solution and the salt concentration without delay.

- Maintaining the concentration of the washing liquid within the maximum solubility and absorption range

- Avoid underdosing (insufficient washing)

- Saving materials by avoiding over-dosage

Cristallization monitoring

Determine the crystallisation parameters for precise detection of the nucleation and saturation point:

- Continuous analysis of undersaturation and oversaturation

- Avoid deviations such as spontaneous nucleation.

- Energy saving through determination of crystal content

- Saving of incoming raw materials by precisely setting the required quality of the finished product

Polymerization process monitoring

- In-line monitoring of the polymerisation reaction

- Detecting process disturbances (delay in the start of the reaction or interruption of the monomer dosing)

- Determining precisely the concentration of trace monomers in the polymer

- Direct measurement of polymer concentration

Detection of phase separation

Many industrial processes have 2 distinct phases:

Ultrasonic technology offers safe detection of phase interfaces and extremely fast for:

- an optimal level of safety (eliminating human risk factors)

- a clear improvement in product yield by reducing waste